Optimizing Systems for Cannabis Greenhouses

All cannabis greenhouses take advantage of sunlight for plant growth, but building construction and climate control strategies can vary so much that some growers say that “if you visit one greenhouse, you have visited one greenhouse.” To optimize building systems for peak productivity, consider managing infiltration through building envelopes so cannabis can be sun-grown while photosynthesis can be optimized with active climate controls.

Seal the Envelope

Greenhouse construction materials range in performance, and influence how growers can control climates to maintain optimized environments for cannabis plant growth and development. The choices you make for building materials and controls strategies for sun-grown cannabis affect your ability to maximize yield and quality characteristics.

Greenhouse buildings are constructed in many different ways, and to describe them, it is useful to understand some building system terms. Thermal envelopes are sometimes referred to as a building’s skin, or shell; you can think of them like your greenhouse’s coat in the winter and sunscreen in the summer. Weatherization describes activities you can do to improve thermal envelopes. Weatherization activities include insulating , which minimize unwanted heat losses and gains, and air sealing, which reduces the infiltration of outside air. Insulation is rated using R-value (a higher value is better) or the U-value (the inverse of R-value, where a lower value is better). Air leakage from infiltration is rated using the number of air changes per hour (ACH, the volume of air moving through a greenhouse each hour described in terms of the size of your greenhouse) or CFMX, the cubic feet per minute at a pressure change of X Pascals (for example, CFM50 tests air leakage rates at a change in building pressure 50 Pa).

There are two major components to greenhouse envelope performance: external coverings and internal equipment. Greenhouse thermal envelope performance is dependent on the design and construction of the facility: building materials and their insulative quality, and the integrity of the envelope’s seal. Contact your local utilities and efficiency programs; air sealing and insulation projects may qualify for financial incentives in your region for new construction and retrofit projects.

Insulation

Greenhouse materials vary; popular covering types include rigid plastic, film plastic, and glass, and each can vary in cost, durability, light transmission, and insulation. Their insulative quality is dependent on the type of covering and its thickness. Rigid plastic products like polycarbonate, acrylic, and fiberglass are popular as they can feature multiple layers of walls which trap air for higher R-value. Film plastic is attractive due to its low cost, but provides no insulation. Some growers use two layers of film and inflate the house with a fan to maintain an air gap. Glass has varying insulation ratings, and can be very well sealed to the structure compared to plastic materials which experience high levels of thermal expansion, which increase infiltration.

Internal weatherization of greenhouses can be necessary depending on location, which affects the amount of solar radiation experienced by your crops, and the quality of the external thermal envelope. Internal equipment like thermal curtains reduce thermal heat loss at night and offer shading in the summer months to reduce cooling loads. Growers in hot climates can reduce heat gain and shade plants, while greenhouses in colder regions can retain heat with a thicker, insulating curtain. Row covers provide additional insulation at the plant level and are used by some growers cultivating plants in hoop houses with film plastic coverings.

Infiltration

Air leakage rates vary depending on methods used for climate control. Ventilated greenhouses passively release hot, humid air via roof vents and are actively ventilated using ventilation fans to cool and dehumidify growing spaces. Some greenhouses include an evaporative cooling pad system to provide additional cooling to the space. Leaks in greenhouse thermal envelopes occur most often around roof vents and ventilation fan and pad wall shutters. Infiltration is much lower in sealed greenhouses. Sealed greenhouses are designed to limit infiltration, yielding much lower ACH which allows for active cooling and dehumidification processes with mechanical equipment. Some sealed greenhouse designs incorporate opaque envelope elements. These designs improve envelope performance through solid insulated walls while still allowing the use of sunlight for cultivation with transparent roofing. Weatherizing greenhouses by sealing them can offer strong energy savings to help lower operating costs and boost profitability by running equipment less often. Improving performance of greenhouse thermal envelopes also can increase harvest quality and yield by providing a more stable and consistent environment.

“This makes a huge difference for precise control of the environment, especially if growers enhance their grow environments with supplemental CO2. Just think about the amount saved,” says Josh Holleb of Ceres Greenhouse Solutions.

Fine-Tune Your Climate Controls

High-performance greenhouses can be ventilated or sealed, but sealed greenhouses can more easily and effectively control the climate for optimal plant expression in quality and yield characteristics. The uncontrolled infiltration and exfiltration of air from traditional ventilated greenhouses introduces significant and unpredictable loads to the space. When coupled with the limited capability of the ventilation and evaporative cooling systems associated with these facilities, maintaining precise environmental targets is a Sisyphean task. Sealed greenhouses can incorporate active mechanical heating, cooling, and dehumidification equipment while ventilating with more precision than roof vents and circulation fans. Efficient HVAC and dehumidification equipment may qualify for financial incentives from your local utilities and efficiency programs; get in touch with them to understand what is available for you depending on the components you are considering replacing or adding.

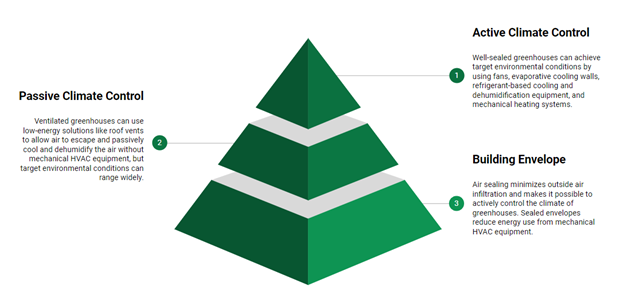

The greenhouse systems pyramid above illustrates the interactive effects of the thermal envelope, and two types of climate control systems: passive and active.

The greenhouse systems pyramid above illustrates the interactive effects of the thermal envelope, and two types of climate control systems: passive and active.

Passive climate control equipment is the lowest first-cost and lowest energy option for greenhouses, but has limited cooling and dehumidification capacity, meaning limited ability to to maintain environmental setpoints, particularly during dynamic or extreme conditions.

Active climate control equipment is able to precisely achieve target environmental conditions by employing more energy-intensive equipment like fans, evaporative cooling walls, radiant heating systems, and refrigeration-based cooling and dehumidification, all of which use electricity or fuel.

With active climate controls, greenhouse growers can employ VPD-based controls while maintaining target environmental conditions more consistently.

“VPD-based controls allow greenhouse growers to set a temperature and humidity range instead of a single fixed temperature,” Holleb says. “For example, when the sun comes out during the first few weeks of flowering, climate controls can maintain VPD by increasing humidity levels and letting the temperature rise, a more efficient strategy for operating mechanical cooling equipment, which reduces operating expenses while maintaining precise environmental setpoints for optimal plant production.”

Tools for Best Practices

- Calculate the heat load of your greenhouse with this calculator to see the impacts of different selections of thermal envelope and target environmental conditions.

- Seal your envelope by weather-stripping around doors and using automatic closers. Consider high-performance greenhouse envelopes that incorporate solid insulated walls and well-sealed thermal envelopes.

- Consider installing insulation board buried below grade at the edge of your greenhouse.

- Ensure thermal curtains are in good operating condition, sealed around edges, free from rips and holes, and ideally, connected with a controller. Consider installing new thermal curtains. Simple payback can range from six months to five years.

- Roof vents operate using actuators that need to be properly maintained and eventually replaced.

- Size ventilation fans properly for your airflow requirements. For hot season growing use 8 CFM per square foot of growing space; for cooler season growing use 2 CFM per square foot.

- Keep air circulating to minimize pathogens that cause disease by installing circulation fans to satisfy flow rates of 25% of your greenhouse’s volume per minute.

- Integrate controls of mechanical cooling, dehumidification, and heating equipment to take advantage of VPD controls for optimizing the performance of your cannabis crop and achieve and maintain target environmental setpoints throughout dynamic and extreme conditions.

Keep an eye out for additional tips in Resource Innovation Institute’s next peer-reviewed Best Practices Guide on Automation & Controls for Cannabis Producers coming this summer. As a non-profit organization, RII brings together producers, utilities, designers, builders and technology providers to help cultivators successfully adopt efficient techniques and ensure resilient harvests into the future.

420 Intel is Your Source for Marijuana News

420 Intel Canada is your leading news source for the Canadian cannabis industry. Get the latest updates on Canadian cannabis stocks and developments on how Canada continues to be a major player in the worldwide recreational and medical cannabis industry.

420 Intel Canada is the Canadian Industry news outlet that will keep you updated on how these Canadian developments in recreational and medical marijuana will impact the country and the world. Our commitment is to bring you the most important cannabis news stories from across Canada every day of the week.

Marijuana industry news is a constant endeavor with new developments each day. For marijuana news across the True North, 420 Intel Canada promises to bring you quality, Canadian, cannabis industry news.

You can get 420 Intel news delivered directly to your inbox by signing up for our daily marijuana news, ensuring you’re always kept up to date on the ever-changing cannabis industry. To stay even better informed about marijuana legalization news follow us on Twitter, Facebook and LinkedIn.